|

|||||

|

|

|

|

|

|||||

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

heavy equipment transport companies: advanced routing, risk, and outcomesI study dispatch logs, permits, and incident data to see what actually moves. Outcomes hinge on engineering prep and schedule flexibility. Price matters, yet wind, escorts, and utility clearances can swing total cost more than a rate sheet. What really drives resultsAcross states, oversize corridors behave differently. Bridge formulas, frost laws, and embargoes reshuffle timing. The best operators build slack, pre-clear alternates, and keep modular configurations ready to rebalance axles fast. I'm mildly unsure any single checklist captures these moving parts.

Net effect: shorter dwell, fewer surprises, and less rework. Not magic - just disciplined options. Field noteLast fall, a nine-axle lowboy moved a lattice-boom crane Tulsa to Pueblo. Crosswinds on Raton Pass forced a southern pivot, adding 120 miles but avoiding a two-day standstill. Flexibility preserved the lift window and the crew's hotel block. A practical sequence

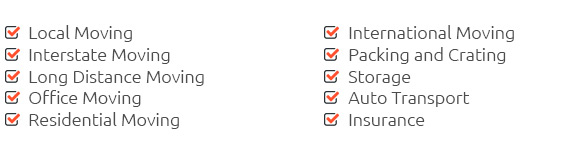

Related Services

|